How to Determine the Correct Amount of Oxygen Absorber for Food

Oxygen absorbers are specialized materials that are commonly used in food packaging to remove oxygen from the packaging environment and to maintain the freshness and extended shelf life of packaged food items. Understanding the correct amount of oxygen absorber is very important during packaging and storage, as it affects how well the packaging preserves the food's nutritional value, texture, and aroma.

They are primarily used in food packaging to prevent oxidation, which can cause spoilage, discoloration, and the growth of bacteria and microorganisms. These absorbers are widely used in the food industry for preserving dried foods, such as grains, nuts, dried fruits, jerky, etc.

Factors to Consider When Choosing Oxygen Absorbers

Type of Food Being Stored

The type of food plays a significant role in determining the amount of oxygen absorber required. Foods with higher fat content or those that are more prone to spoilage may require larger or additional absorbers.

Packaging Material

The material of the packaging also affects the efficiency of oxygen absorbers. For example, vacuum-sealed bags or Mylar bags with low oxygen permeability are more effective in conjunction with oxygen absorbers compared to regular plastic bags.

Storage Conditions

Environmental factors such as temperature and humidity can influence the effectiveness of oxygen absorbers. Storing food in a cool, dry place will enhance the efficiency of the absorbers.

Calculating the Correct Amount of Oxygen Absorber

Calculating the correct amount of oxygen absorber involves several steps and considerations. Here is a detailed overview of the process:

Determining the Volume of the Container

The first step in calculating the correct amount of oxygen absorber that is required is to determine the volume of the container in which the food will be stored. This can be done using the formula for volume calculation based on the shape of the container, for example, cubic volume for rectangular containers and cylindrical volume for round containers.

Calculating the Oxygen Volume

Next, you need to calculate the volume of oxygen present in the container. Since oxygen makes up about 21% of the air, you can calculate the oxygen volume by multiplying the total volume of the container by 0.21.

Determine the Correct Amount of Oxygen Absorber

To determine the volume of oxygen that penetrates into the packaging during shelf life, you need to consider the oxygen permeability of the packaging material, the surface area of the packaging, and the shelf life of the packaged food. The oxygen permeability of the packaging material is typically provided by the supplier and is usually measured in units of cubic centimeters per square meter per day (cc/m²/day).

The surface area of the packaging material can be measured directly or calculated using the formula for the surface area of a rectangular prism. The shelf life of the packaged food is typically specified by the manufacturer or determined through testing and experimentation.

Oxygen Absorber Requirements Size Chart

OxySorb - Oxygen Absorber Requirements Size Chart Guide

|

Types of Packed Food |

Up to 100gm |

100gm to 250gm |

500gm to 1Kg |

1 to 2 Kg |

2 to 8 Kg |

10 Kg- 15kg |

20-25kg |

|---|---|---|---|---|---|---|---|

|

Dry Fruits & Nuts |

20cc |

50cc |

100cc |

200cc |

500cc |

1500cc |

3000cc |

|

Dehydrated Fruits and Vegetable

|

20cc |

50cc/100cc |

200cc |

500cc |

500cc /1500cc |

3000cc |

3000cc - 2 to 3 pcs |

|

Rice, grains (wheat berries, oats, etc.) |

20cc |

20cc/50cc |

100cc |

200cc |

500cc |

1500cc |

3000cc |

|

Dried garlic, onion slices, flakes-powder |

20cc |

50cc |

100cc |

200cc |

500cc |

1500cc |

3000cc |

|

Flour, pancake mix, fine powders |

20cc |

50c |

100cc |

200cc |

500cc |

1500cc |

3000cc |

|

Spices & Jaggery |

20cc |

50c |

100cc |

200cc |

500cc |

1500cc |

3000cc |

|

Pasta, Ready to Eat pack

|

20cc |

20cc/50cc |

100cc |

200cc |

500cc |

1500cc |

3000cc |

|

Sweets & Namkeen

|

20cc |

20cc/50cc |

100cc |

200cc |

500cc |

1500cc |

3000cc |

Important Note: The oxygen absorber sizes mentioned in the chart are based on pouch packaging.

For jars, always consider the internal air space and choose a lower cc size absorber to ensure effective oxygen removal.

Note on Volumetric Products:

Using these values, you can calculate the volume of oxygen that penetrates into the packaging during the shelf life. This is done by multiplying the oxygen permeability of the packaging material by the surface area of the packaging and the shelf life. For example, if the oxygen permeability is 10 cc/m²/day, the surface area is 1000 cm², and the shelf life is 6 months, the volume of oxygen that penetrates into the packaging during the shelf life would be:

10 cc/m²/day × 1000 cm² × 183 days (6 months) = 183,000 cc

This value represents the total volume of oxygen that penetrates into the packaging during the shelf life and must be taken into account when determining the correct amount of oxygen absorber needed.

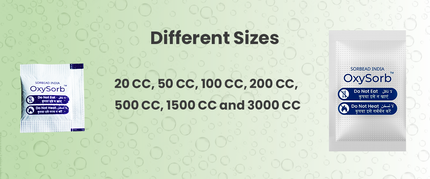

Selecting the Right Oxygen Absorber

Oxygen absorbers come in various capacities, typically measured in cubic centimeters (cc). Common sizes include 100cc, 200cc, 500cc, and 1500cc. To determine the appropriate size, match the calculated oxygen volume with the corresponding oxygen absorber capacity.

For example, if your container has a volume of 10 liters (10,000 cubic centimeters), the oxygen volume would be 2100 cubic centimeters (10,000 x 0.21). You would then choose oxygen absorbers that can handle a total of 2100 cc. This might mean using multiple absorbers to reach the desired capacity.

Sorbchem India is the leading manufacturer and supplier of premium quality Oxygen Absorbers that can be applied across various applications to enhance the shelf life of products and maintain optimal storage conditions.

FAQs-

1. How do I know if my oxygen absorber is working effectively?

Once exposed to oxygen, it will immediately start to oxidize, capturing the surrounding oxygen. Check for signs of activation, such as a warm or clumpy texture. If the absorber is fully loaded it will no longer have the capacity to absorb additional oxygen.

2. Can I heat oxygen absorbers with my food?

Most oxygen absorbers cannot be heated in a microwave, as the packet can ignite or burst. Check the manufacturer's instructions for any heat-resistant options.

3. How do I prevent air loss when using oxygen absorbers?

Use absorbers that generate CO2 to maintain air volume, or replace oxygen with an inert gas during packaging and ensure the complete sealing of the container.